- Produktinformationen

- Model size: 16.8x12.8x10.6 cm

- Package size: 20.5x18.8x6.3 cm

- Number of components: 104

- Estimated time for assembly: 2.5 hours

- The model kit comes with a QR-code that will forward you to the learning guide about the mechanism, the principal of its working, the main characteristics, formulas, and interesting assignments.

- Dive into augmented reality and look at how the Variator works. Interact with the model via a special AR application from Ugears

- key

- drive cone pulley

- driven cone pulley

- reducer

- belt

- pedal

- body

- transmission fork

- Wooden details pre-cut with a precise high-tech laser in high-quality plywood boards, as well as other materials required for assembly. The models need no glue or additional instruments to build. The details come out of the board with a slight push.

- Step-by step illustrated assembly instruction manual.

- Practical lab tasks with use of your model.

- QR-code to download a pocket study guide about your model, its mechanism, principle of its working, main characteristics, physical and mechanical formulas, and fun practical tasks.

- QR-code to download AR-application. Fascinating innovation from Ugears – new drive to learn more new things!

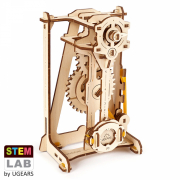

Ugears STEM LAB - Variator - Educational mechanical model kit

Assemble it and discover the principle of working of the Variator.

Find out about the Variator

The Variator is a device that transfers and adjusts the engine torque by changing the ratio of gears. Gear ratio can change automatically, manually or within a pre-set program. The term most drivers and automobile enthusiasts are more accustomed with is Continuously Variable Transmission, or CVT. With the Ugears Variator model of the STEM lab collection you can learn and comprehend one of the most important parts of a car without soiling your hands in machine oil!

Who invented the Variator and when

The roots of the modern car CVT go back to 1879 when an American entrepreneur and a pioneer of the automobile industry Milton Othello Reeves invented a device for use in sawmilling that he then called a variable-speed transmission. Later he began fitting this transmission to his cars. The Reeves CVT was also used by several other manufacturers.

Use

The CVT is used in mechanisms, in which a continuous range of gear ratios must be changed seamlessly: cars, motor scooters, snowmobiles, quadracycles, conveyors, metal-cutting machines, etc. To have a better idea about how it is used in different types of equipment, try the AR application that comes with the Ugears STEM model.

The Variator’s design and how it works

The Mechanical Variator of the Ugears STEM lab collection is a fully functional wooden replica of a Belt-driven Friction Cone CVT. The Cone CVT varies the drive ratio by moving a wheel or belt up and down the axis of conical roller. In the Ugears Variator model, the belt, powered manually via the reducer, transfers the rotation to the driven cone pulleys. Use the transmission fork to change gears and observe how the speed of the driven cone pulley drops or rises while the drive cone pulley’s speed remains the same. Due to the open design of the model, you will be able to see the whole process.

The mechanism of the Variator is composed of:

Ugears STEM models are designed to suit different age groups with a special focus on learning component. The assembly of the model will be interesting and won’t take much time.

STEM lab Model kits come with all you need in a box.

Just like the rest of Ugear’s collections, putting STEM lab models together is fun and comprehensive: everything you need to build, learn, and discover comes in a box. There you will find:- Features

-

- Teile

-

- Beliebtes Zubehör

- Downloads

-

- GPSR

-

Hersteller

Registrierte Kontaktinformationen des Herstellers des Produkts.

Name Ugears International Trade Company SIA Contact Ugears Address Baltä iela 1B

LV-1055 Riga Land Latvia Telefon +371 25 663 061 E-mail customerservice@ugearsmodels.com Webseite https://www.ugearsmodels.com

- Tab

-

Weitere Produkte anzeigen